AMERICAN COUNCIL OF ENGINEERING COMPANIES (ACEC)

By Samuel Greengard

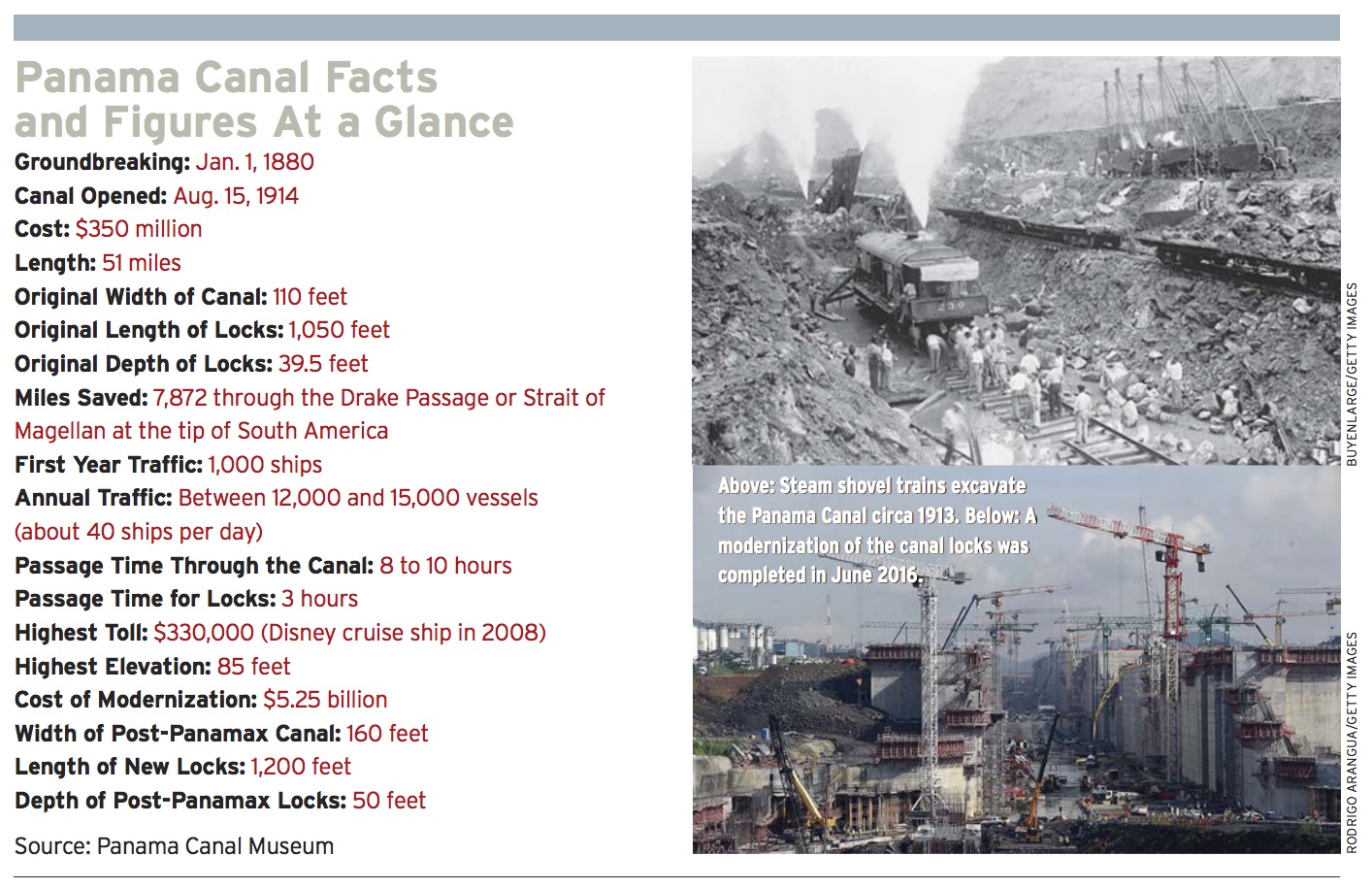

When engineering and construction crews completed the massive Panama Canal modernization project in June 2016, it was a defining moment in global commerce.

When engineering and construction crews completed the massive Panama Canal modernization project in June 2016, it was a defining moment in global commerce.

The $5.25 billion upgrade, which allowed new and significantly larger ships to pass through the series of new locks, represented nothing less than a sea change for shippers and ports worldwide.

“There’s a recognition that ports must support larger ships and improved economies of scale,” says Jeff Schechtman, vice president at WSP | Parsons Brinckerhoff, which specializes in port modernization. “It’s something that impacts the entire port industry.”

As shippers switch to larger vessels—including so-called postPanamax ships—there’s a need for deeper and wider berths, larger cranes, upgraded port infrastructure and changes to railways and highways that connect to the ports. These projects, which involve everything from dredging channels and building new container yards to installing new cranes and computer software, typically run into the billions of dollars and require precise coordination among numerous companies and agencies, including the Army Corps of Engineers, state and local officials, and private companies.

“There’s been an infrastructure investment race taking place, particularly on the Eastern Seaboard of the United States, to meet the demands of larger vessels,” says Patrick King, global director, Ports & Maritime at CH2M, the program manager for the Panama Canal project. Not surprisingly, the scale of this type of work is enormous—sometimes spanning a decade—and involves a great deal of engineering and construction acumen, not only to modernize the port but also to keep it operating while improvements are taking place.

“There’s been an infrastructure investment race taking place, particularly on the Eastern Seaboard of the United States, to meet the demands of larger vessels,” says Patrick King, global director, Ports & Maritime at CH2M, the program manager for the Panama Canal project. Not surprisingly, the scale of this type of work is enormous—sometimes spanning a decade—and involves a great deal of engineering and construction acumen, not only to modernize the port but also to keep it operating while improvements are taking place.

According to the American Association of Port Authorities (AAPA), ports and their partners are investing $155 billion over the next five years in infrastructure improvements. Yet, at the same time, it found that one in three U.S. ports requires at least $100 million in intermodal upgrades to handle projected 2025 cargo and freight volumes. All of this creates new challenges and opportunities for A/E/C firms.

According to the American Association of Port Authorities (AAPA), ports and their partners are investing $155 billion over the next five years in infrastructure improvements. Yet, at the same time, it found that one in three U.S. ports requires at least $100 million in intermodal upgrades to handle projected 2025 cargo and freight volumes. All of this creates new challenges and opportunities for A/E/C firms.

“These projects change ports and the surrounding areas in significant ways,” says Jamie Gwaltney, vice president at Moffatt & Nichol, which has handled economic forecasting, planning, engineering and construction management for the Georgia Ports Authority (GPA) and other ports and terminal operators.

Making Waves

It’s no secret that business and commerce have become increasingly global. AAPA notes that about $6 billion worth of goods— automobiles, appliances, electronics, furniture, petroleum and myriad other products—move to and from overseas markets every day. The overall impact of U.S. seaports on the domestic economy is more than $4.6 trillion, which has resulted in larger cargo and tanker ships.

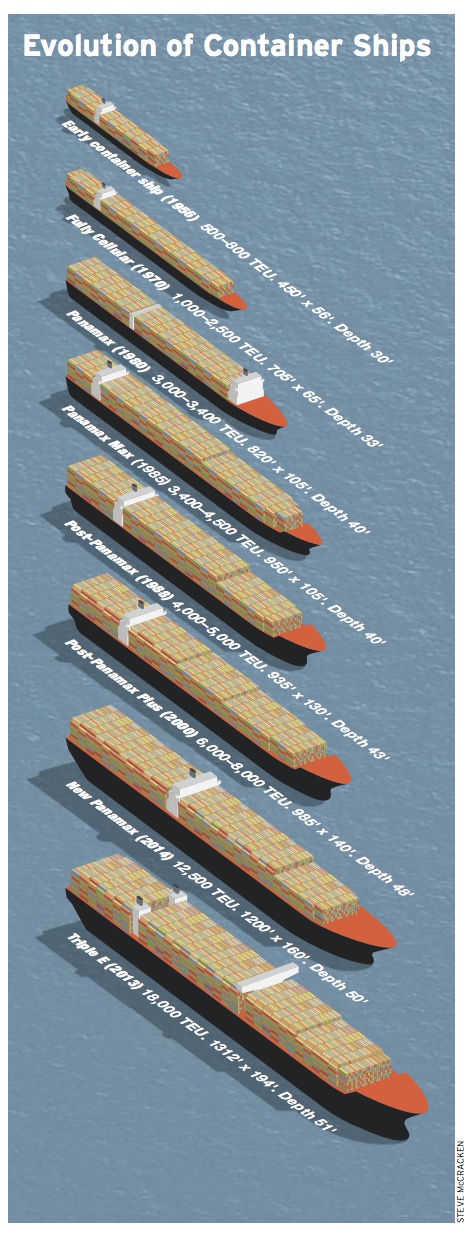

“The shipping industry has had to continually reboot and adjust its business model to accommodate larger ships,” says John Young, director of freight and surface transportation policy at AAPA. In 1956, a typical vessel carried about 500 containers. Even a decade ago, a typical vessel carried about 5,000 20-foot equivalent units (TEU). Today, the largest ships accommodate up to 20,000 TEUs in 20- to 40-foot containers, Young says.

The ships aren’t going to get smaller. By the end of 2017, about 60 percent of the world’s container ship capacity will be on vessels larger than those that the old Panama Canal could accommodate, says Jim Newsome, president and CEO of the South Carolina Ports Authority. The new Panamax ships are sometimes as long as 1,200 feet and require a channel depth of about 50 feet.

That means the ports have to keep up. The shipping industry isn’t waiting for major ports to expand before building and deploying larger ships designed to lower costs and increase efficiency.

In 2006, the Panama Canal Authority estimated 37 percent of the world’s container ships would be too large to pass through the locks by 2011. This meant that many vessels would instead embark on a longer trip through the Suez Canal and sail around the Cape of Good Hope in Africa or Cape Horn in South America. The subsequent expansion of the Panama Canal, which took place from 2007 to 2016, added two new flights of locks adjacent to two existing sets of locks (there are now three parallel sets of locks at the canal). The new locks are 1,400 feet long, 180 feet wide and 60 feet deep. The improvements will allow the Panama Canal to increase the tonnage flowing through it from a record 340.8 million tons in 2015 to an estimated 524 million tons in 2020.

Now several U.S. ports—including Baltimore, Miami, New York/New Jersey, Los Angeles, Seattle, Oakland (California), Houston, Norfolk (Virginia), Charleston (South Carolina), Savannah (Georgia) and Philadelphia—are following suit and modernizing facilities so that they can handle the larger ships. But it’s no small task.

For example, The Port Authority of New York & New Jersey is in the final stages of a multiyear project to accommodate post-Panamax cargo vessels. It is dredging the harbor to a 50-foot depth, raising the Bayonne Bridge to allow ships to pass, and investing in a $600 million intermodal rail program. Meanwhile, the Mississippi Gulf Coast modernization will cost $570 million, and PortMiami is undergoing $1 billion in infrastructure enhancements.

The Port of Charleston illustrates just how complex it is to modernize a port. It is undergoing more than $1.3 billion in upgrades over a 10-year span. “A project of this magnitude requires more than simply deepening the channel,” Newsome says. “We built terminals to handle containers in the 1980s, and we never envisioned that we would be facing 2,000 to 4,000 TEU ships.” Deepening the harbor by 7 feet to a total of 52 feet is only the start. South Carolina Ports Authority refurbished the entire over-the-water structure of the wharf— including adding pilings and building a new fendering system that absorbs the force of the ships when they berth and strike surrounding structures. It has also meant upgrading to new cranes with a lift height of 155 feet rather than 115 feet and rebuilding an intermodal container transfer facility. The state of South Carolina has also invested about $200 million to improve surrounding roads.

At the 1,200-acre Garden City Terminal, the Port of Savannah is undergoing a massive $706 million modernization that is scheduled for completion in 2020, which will push capacity from about 4.5 million 20-foot equivalent container units to 6.5 million TEUs. The harbor already has 22 neo-Panamax ship-to-shore cranes in place, and it will have 30 by 2018, says Griff Lynch, executive director of the GPA. At the same time, the Savannah Harbor Expansion Project, currently underway, will deliver a river channel that is 47 feet at mean low water and 54 feet deep at high tide. In addition, the state has opened a limited access truck route extending from Interstate 95 to just outside the gates of Garden City Terminal, and the federal government has funded $44 million in rail improvements surrounding the facility.

“A major challenge facing U.S. ports is sufficient infrastructure to accommodate today’s larger ships,” Lynch says.

Download full article (PDF): Riding the Wave

Download latest issue of ACEC’s Engineering, Inc.

About the American Council of Engineering Companies

About the American Council of Engineering Companies

www.acec.org

The American Council of Engineering Companies (ACEC) is the voice of America’s engineering industry. Council members – numbering more than 5,000 firms representing more than 500,000 employees throughout the country – are engaged in a wide range of engineering works that propel the nation’s economy, and enhance and safeguard America’s quality of life. These works allow Americans to drink clean water, enjoy a healthy life, take advantage of new technologies, and travel safely and efficiently. The Council’s mission is to contribute to America’s prosperity and welfare by advancing the business interests of member firms.

Tags: ACEC, American Council of Engineering Companies, Cargo, Engineering Inc., Freight, Panama Canal, Panamax, Shipping

RSS Feed

RSS Feed